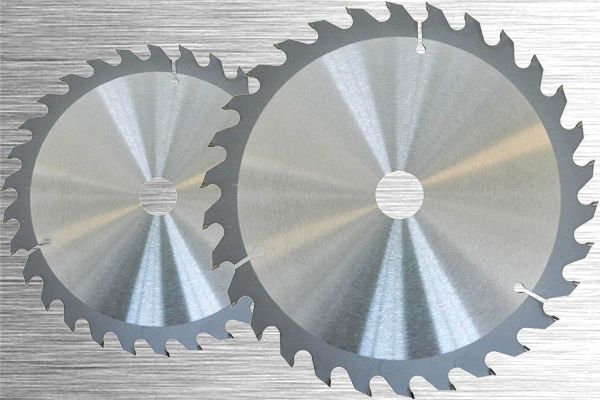

The utility model relates to a particle board sawing a polycrystalline diamond saw blade. The name is a particle board sawing a polycrystalline diamond saw blade. The utility model comprises a circular plate-shaped substrate, and teeth are arranged around the substrate. The shape of the upper and outer ends of the teeth after inlaying the polycrystalline diamond layer, the side of the tip is an inclined plane, and the inclined angle of the inclined plane is 15 degrees. The sawing also has the advantages of good sawing quality, low resistance, low noise, and long service life; the side of the tip is an inclined plane, and the inclination angle of the inclined plane is 15 degrees, which can achieve better results.

Main claim:

1. Granular particle board sawing polycrystalline diamond saw blade, comprising a base body, said base body is a disc-shaped structure with teeth around the base, characterized in that a polycrystalline diamond composite sheet is welded in front of said teeth, That is jagged.

2. The polycrystalline diamond saw blade according to claim 1, characterized in that the saw teeth of the polycrystalline diamond composite blade are divided into two types, namely the first polycrystalline diamond composite blade and the second polycrystalline diamond composite. Sawtooth, the first polycrystalline diamond composite sheet sawtooth and the second polycrystalline diamond composite sheet sawtooth have a chamfered structure on the side of the tooth top, and the side of the first polycrystalline diamond composite sheet sawtooth has a chamfered line that is good at the second polycrystal The chamfer line of the side of the diamond chip on the side of the diamond chip, the sawtooth top surface of the first polycrystalline diamond composite sheet is higher than the sawtooth top surface of the second polycrystalline diamond composite sheet, the saw tooth of the first polycrystalline diamond composite sheet and the second polycrystalline diamond composite sheet The serrations are arranged at a distance on the teeth around the base body.