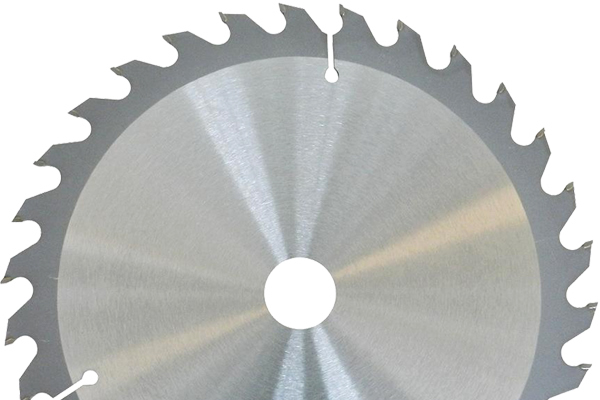

I have discussed the value of diamond saw blades in the enterprise with many friends in wood-based panel companies. Many people think that diamond saw blades are expensive and the one-time investment is too large for the company to bear: especially during the economic bleak period, the company's profits are thin , Corporate livelihoods are struggling. Then let's analyze how diamond saw blades can benefit enterprises in actual use.

I. Selecting PCD polycrystalline diamond saw blade can traverse product quality and increase product competitiveness:

PCD polycrystalline diamond saw blade has excellent abrasion resistance, super hardness, long cutting period, low friction coefficient of diamond saw blade, small cutting resistance, small end runout, small thermal deformation, high machining accuracy: diamond The affinity between the saw blade and the non-metallic material is very small. During the processing, the chips are not easy to adhere to the tip of the knife to form a built-up edge. In the case of cold cutting of the plate, it is not easy to have viscous edges. Together with reducing the damage rate of the mechanical arrangement of the equipment, the edge of the cut board becomes smoother and smoother, which is more perfect for the overall quality of the product. The characteristics of PCD polycrystalline diamond are as follows:

1. The hardness of PCD can reach 8000HV, which is 80 to 120 times that of cemented carbide;

2. The thermal conductivity of PCD is 700W / mK, which is 1.5-9 times that of cemented carbide, and even higher than PCBN and copper, so PCD cutters are sensitive to heat transfer;

3. The friction coefficient of PCD is generally only 0.1 ~ 0.3 (the friction coefficient of cemented carbide is 0.4 ~ 1), so the PCD tool can significantly reduce the cutting force;

4. The thermal expansion coefficient of PCD is only 0.9 × 10 -6 ~ 1.18 × 10 -6, which is only equivalent to 1/5 of the cemented carbide. Therefore, PCD tools have less thermal deformation and high machining accuracy;

Second, the hidden value of PCD polycrystalline diamond saw blade in actual use:

The ability of diamond saw blades to save energy and reduce emissions and to hide hidden benefits in actual use cannot be underestimated. The replacement time of the alloy saw blade listed in the above table is the key to trekking efficiency. It is particularly important in modern enterprises where time is money. We make a simple calculation and produce 220,000 cubic meters of sheet material per year according to a production line. The alloy saw blade needs to be replaced once every 300 cubic meters of cutting, divided by 220,000 divided by 300, and the saw blade needs to be replaced about 733 times: each saw blade is replaced for about 10 minutes (a single saw blade requires five minutes, the standard saw There are two saw blades, so it takes 10 minutes). 733 times multiplied by 10 minutes equals 7330 minutes, and 7330 minutes divided by 60 minutes (one hour and 60 minutes) is approximately 122 hours, which means that 122 hours of production time in a year is wasted on replacement saw blades: 122 Hour divided by 24 hours (24 hours a day), the result is equal to 5 days. This is the time cost, so with the time cost, let's calculate the value of the resources consumed by the enterprise. It is mainly reflected in the following three aspects:

1. Huge waste of power resources:

After we combined with the production department, we learned that the total power of the motor in the sanding sawing section is 2000 kilowatts, which is converted at 50% of the load. Under no-load conditions, the power consumption is 1000 kilowatts per hour, and then according to our previous calculations According to the calculation of 122 hours wasted in a year, 122,000 kilowatts of electricity are wasted in a year. According to the electricity price of 0.68 yuan / degree, the annual electricity cost is 82960 yuan (122000 * 0.68). Just this humble ten minutes, an annual cost of 80,000 Multi-money electricity bills.

2. Consumption of human resources:

It can be seen from the above that the average annual replacement time of the saw blade is 122 hours, divided by 24 hours, and the result is 5 days. A sanding sawing section also requires at least 4 employees, which means that these 5 days Our four employees did not generate benefits, but the company still pays employees. How much this detail is determined according to the salary level of the company.

3. Loss of hidden benefits:

As a modern enterprise, the cost of time is huge, because the company must consume every time it does not generate benefits. We know that every year the company spends 5 days to replace the saw blade, this time is useless Come to produce, to be honest, it is a waste. If we use these 5 days to produce, we can calculate how much benefit we can travel. With reference to the production line that produces 220,000 cubic meters of board per year, the average output is 10 months a year. That is to say, 22,000 cubic boards are produced in a month, and they are evenly calculated to 30 days each month, and about 730 cubic meters are produced every day. In 3 days, 3,650 cubic boards can be produced, and 35 cubic sheets are calculated for each cubic board for 5 days. About 130,000 pieces are produced less, and the most saved account is made. A board earns 3 yuan, and it earns about 400,000 less a year. Plus the previous electricity bill of more than 80,000, plus the salary of employees, the accumulated value of the cost of trust you can feel it.